Holder

Applications:

- •Spotting, engraving, grooving and chamfering on milling machines, machining centers.

- •Spotting, facing, turning on CNC Lathes.

Insert

- Multifunction for 90° spot drill

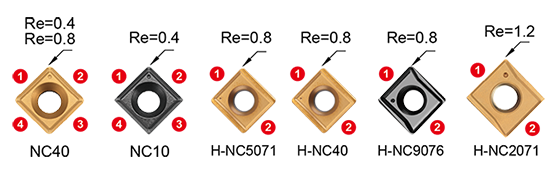

- • NC40 :

- General purpose, universal grade for all unhardened steel.

- Each insert has 4 cutting edges.

- • NC10 :

- High positive angle and fully ground cutting edge and relief angle.

- Universal grade for non-ferrous metal, cast iron and stainless steel.

- Each insert has 4 cutting edges.

- • H-NC5071 :

- For carbon steel C>0.3%, high alloy steel C>0.3% and cast iron.

- Each insert has 2 cutting edges.

- • H-NC40 :

- For carbon steel C<0.3%, low alloy steel C<0.3%, stainless steel, non-ferrous and titanium.

- Each insert has 2 cutting edges.

- • H-NC9076 :

- High positive geometry and sharp edge.

- For non-ferrous material such as aluminum, titanium, brass, copper and long cutting chip metal.

- Produces excellent surface finish on non-ferrous metal.

- Each insert has 2 cutting edges.

Starter Package

Comparison