Successful Story- Machining Duplex stainless steel by NC Helix Drill

2021-06-08

NC Helix Drill vs JIS SUS 329-J4L / DIN EN 1.4507 /S32205/ X2CrNiMoCuN25-6-3 (Duplex stainless steel)

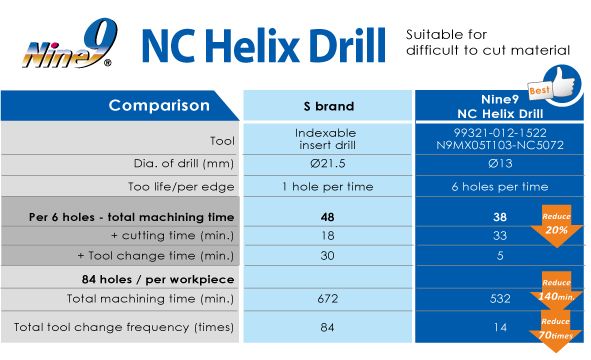

-> In Japan, a customer used indexable insert drill to drill duplex stainless steel which is difficult to cut due to the temperature and wearing issues. It's a headache for them to change new insert after drilling 1 hole. The tool life is too short and they spent a lot of time to change a new insert. So, they looked for a solution to reduce tool changing time and total machining time.

There are 84 holes per workpiece, hole diameter is 21.5mm and depth is 42mm. Machine with external coolant, the original total machining time including tool changing is 672mins. After using NC Helix Drill, the total machining time reduce to 532 mins. Save 20% of total machining time.

The customer was satisfied and said NC Helix Drill is an efficient tool for machining difficult_to_cut material. It reduces tool change times, and also has better tool life to save our tool inventory and cost.

More info please visit: https://nine9.jic-tools.com.tw/nc-helix-drill.htm