- Home

- Solution

Solution

A Successful Application – MCC Makes threading Hard Materials Easy!

Engraving -From Burrs to Clean Edges

Using Nine9 MCC Mill for Tapered Pipe Threads (Rc 1/4–19) on SUS304, High Productivity Without Pre-Milling

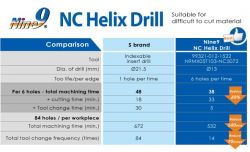

How NC Helix Drill Cut Minimum Ae by Zigzag programing?

Deep hole drilling by NC Helix Drill

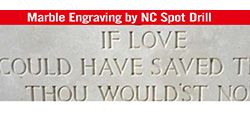

An Impressive Engraving Result of NC Spot Drill

To showcase the engraving capabilities of the Nine9 X060 Engraving Tool.

Indexable center drill application for gear shaft center hole

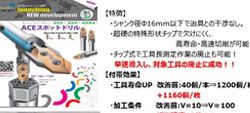

ACE spot drill get comments from users from Japan and USA

Tool life comparison: i-Center with HSS center drill

Widening a deep hole (6xD) in stainless steel by NC Helix Drill

Marking on medical probes by Nine9 engraving tool

Engraving tool engrave mark on brake rotors (machine components)

Engraving on Rear Limited Slip Differential Aluminum Alloy Cover

Machining Difficult-to-Cut Materials: JIS: SUS 329-J4L / S32205

Trouble shooting in Milling

Nine-9 NC Helix Drill cut multi-stepped hole in AL6061T6 by one tool

Successful Story- Nine9 engraving tools, helix drill vs. car forged wheel

Deburring Mill for Side Grooving - Tool Life Challenge

Achieving Breakthrough Performance with Nine9 ACE Spot Drill

Revolutionize Your Drilling with the Nine9 NC Helix Drill

Are you tired of struggling to deburr narrow spaces?

Corner rounding RC10 with up milling, smoother and better

Corner rounding RC10 with up milling, smoother and better

Create a QR code on metal component by Nine9 spotting tool

Successful Story- Chamfer Mill is an excellent tool to improve the performance and reduce cutting time.

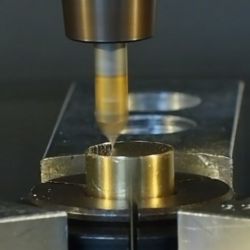

Ø36mm NC Helix Drill making Ø60mm hole by Fanuc Tapping Center

Are you sensitive in time and cost saving while machining center hole?

Art of Nine9 X060 fine engraving tools

Successful case- i-Center comparison with HSS center drill

To machining Ø60mm blind holes of 50/100/150mm individual depth just by one NC Helix Drill.

Successful Story- Machining Duplex stainless steel by NC Helix Drill

Deep hole drill dia. 40 x 390mm on pulley by Nine9 10D indexable drill

Grooving and logo carving all around the cylinder on face mask ultrasonic welding drum by Engraving tool

How to avoid cutting load and scratch happen on workpiece

NC Helix Drill Excellent swarfs control for modern automation

Successful Application of Ergo milling cutter

Machining Inclined Hole and Step Hole on Rounded surfaces in Aluminum by NC Helix Drill

Just 2 tools can machining Forged Aluminum for Car Wheel and Balanced Ball Joint

Using NC Helix Drill to Optimize Machining Process

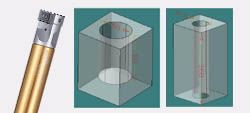

How to improve the efficiency when cutting different diameters and hole depths

Just One NC Helix Drill to Drill Different Diameters and Hole Depth possible up to 6xDc

Machining a cover of scooter engine Work piece material: Die casting, Al-alloy, ADC-12(A383)

Engraving tools with carbide insert comparison with Ball nose end mill 0.4R

Engraving tools with indexable carbide inserts using on tire molding

From hand hitting to engraving with indexable engraving tools

Its not only an example by 45 degree Indexable Engraving tools

To engrave character on ASP23 HSS material by indexable engraving tool

Indexable Center drill comparison HSS center drill

More than 8 times tool life is proved about indexable center drill

Mini indexable center drill improved center hole drilling time

Nine9 i-center runs well both in high and low spindle speed machines

lower spindle power consumption with Nine9 hole making tool

NC Helix Drill cutting different material because special insert geometry

NC Helix Drill to cut Titanium in different conditions

One Nine9 hole making tool performs multiple patterns

Producing a dia 60 x 27mm hole with just one hole making tool

Replace your end mill with an Nine9 interpolation cutter

To produce step hole dia. 53.5 & dia. 45 with one tool by hole making tool

User interview of boring tool

Indexable corner rounding insert comparison with solid carbide tools.

142° NC Spot Drill with carbide insert help you do not have to do the pre-drilling anymore.

Excellent groove tool from Nine9 standard indexable tooling_ 99616-14 and 99616-13V.

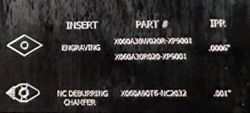

One Nine9 NC Spot Drill with indexable carbide insert performs spotting, grooving, engraving and chamfering.

Nine9 45° Chamfer Mill reduce the cutting time. Making easy and easier.

One tool Nine9 chamfer mill performs 90 degree counter sink and 45 degree chamfering.

25 X 25 square shank holder for indexable center drill