99616-C02, C04. C06

- Made from hot working steel and hardened.

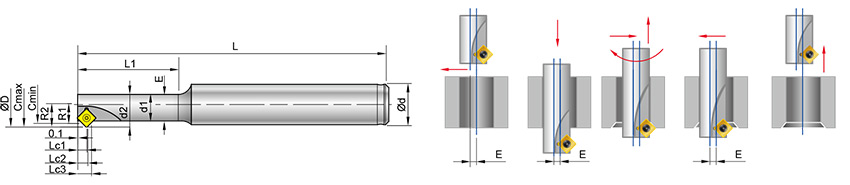

- Elliptical necked bar to optimize tool strength

Inserts

- Each insert has 4 cutting edges.

- NC2032 : For carbon steel, alloy steel, cast iron and hardened steel up to 56HRC.

Long tool life.

- NC9071 : For no ferrous metal.

Sharp cutting edge, excellent surface finish.