- Home

- Solution

Solution

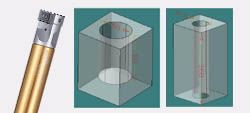

How NC Helix Drill Cut Minimum Ae by Zigzag programing?

Deep hole drilling by NC Helix Drill

Widening a deep hole (6xD) in stainless steel by NC Helix Drill

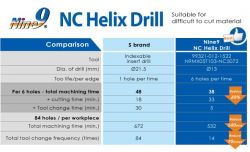

Machining Difficult-to-Cut Materials: JIS: SUS 329-J4L / S32205

Nine-9 NC Helix Drill cut multi-stepped hole in AL6061T6 by one tool

Revolutionize Your Drilling with the Nine9 NC Helix Drill

Ø36mm NC Helix Drill making Ø60mm hole by Fanuc Tapping Center

To machining Ø60mm blind holes of 50/100/150mm individual depth just by one NC Helix Drill.

Successful Story- Machining Duplex stainless steel by NC Helix Drill

How to avoid cutting load and scratch happen on workpiece

NC Helix Drill Excellent swarfs control for modern automation

Machining Inclined Hole and Step Hole on Rounded surfaces in Aluminum by NC Helix Drill

Using NC Helix Drill to Optimize Machining Process

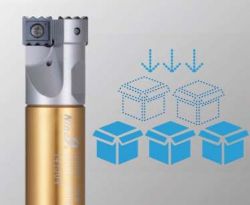

How to improve the efficiency when cutting different diameters and hole depths

Just One NC Helix Drill to Drill Different Diameters and Hole Depth possible up to 6xDc

lower spindle power consumption with Nine9 hole making tool

NC Helix Drill cutting different material because special insert geometry

NC Helix Drill to cut Titanium in different conditions

One Nine9 hole making tool performs multiple patterns

Producing a dia 60 x 27mm hole with just one hole making tool

Replace your end mill with an Nine9 interpolation cutter

To produce step hole dia. 53.5 & dia. 45 with one tool by hole making tool