User interview of boring tool

User interview about boring tool

I need low cost tools

“ I need low cost tools, ” stated Mr. Coetzee, a South African who is the owner of the TMPC co. Ltd. - a design and machining company he established in Taiwan 12 years ago. “The cost of a crash or damage caused by human error is too expensive!”, said Mr. Coetzee. “The carelessness of the operator is our highest concern due to its high cost.”

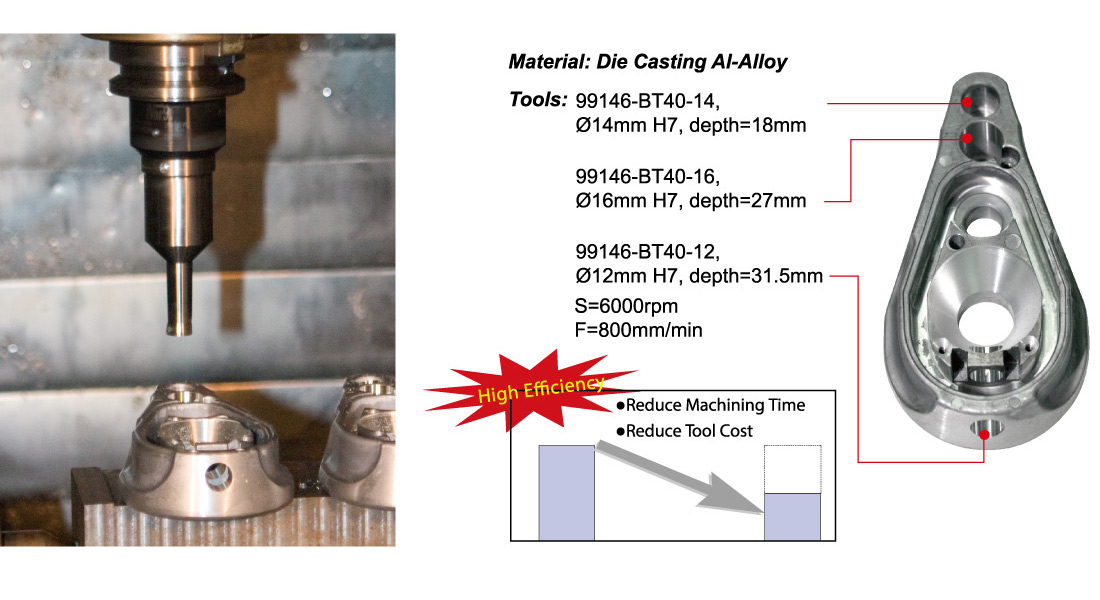

“I have been producing more than 5000 types of parts, mostly for bicycles, motorcycles and the sports industries. The company specialize in aluminum machining and the major clients are in the USA.” TMPC has 21 CNC machines which operate 24 hours a working day. “When I saw the flyer of the Nine9 boring bar, I didn’t think it could work. It seemed too simple to convince me, and the adjustment range appeared to be too small.” said Mr. Coetzee who graduated from technical college having good knowledge of both machine programming and applications. He had been satisfied with Big+Kaisher and D’Andrea boring tools.

In order to shorten the delivery time and offer more competitive prices to beat the competition, he designed special fixtures to optimize the application of machines, as well as implementing the use of special high efficiency tools. “I like to use special combination tools, which are more efficient at a lower cost, and I also like to create new methods of using tools”.

“ I have many Nine9 boring tools which are great for production work,” Mr. Coetzee said. “Lower cost for boring the pin holes, bearing holes which are applied on all common parts repeatedly. Using fixed diameter Nine9 boring tool, even with the small adjustment range is enough to maintain the tolerance in H6 or H7. Nine9 tools are very stable to use when high speed machining is required at low cost.”