Holder

Applications :

- •spotting and chamfering on milling machine, machining centers.

Insert

- Single cutting edge design gives higher precision when spotting.

- Each insert has 2 cutting edges.

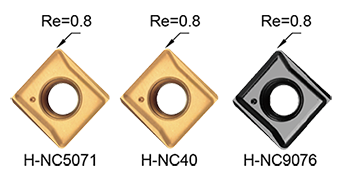

- H-NC5071 : For carbon steel C>0.3%, high alloy steel C>0.3% and cast iron.

- H-NC40 : For carbon steel C<0.3%, low alloy steel C<0.3%, stainless steel, non-ferrous and titanium.

- H-NC9076 : For non-ferrous material such as aluminum, titanium, brass, copper and long cutting chip metal.

Sharp edge and excellent surface finish on non-ferrous material.