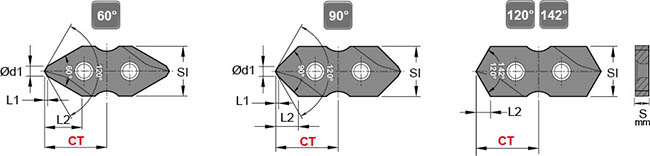

Insert

- • 2-flutes deged is symmetric, it reduces the lateral force.

- • The dual point angles ensure strength at the centre to prevent fracturing.

- • Each insert has 2 cutting edges.

- NC2057: Universal grade for alloy steel and cast iron.

- NC5254: For stainless steel.

- XP9000: For non-ferrous material such as aluminum, titanium, brass, copper and long cutting chip metal. High positive geometry and sharp edge produces excellent surface finish.

Screw Fit Cutter

- • Made of hardened high alloy steel, 53 HRC.

- • Internal coolant.

Cylindrical shank

- • Made of hardened high alloy steel, 58 HRC.

- • Internal coolant.