Cylindrical Shank

Integrated ER16 taper-shank

• An integrated ER taper-shank cutter, eliminate assembly tolerance.

Optimize the rigidity. Increase tool life. Better surface finish quality.

• The cutter has minimal assemble parts, changing tool takes just few seconds.

• Perfectly suitable for driven tools and spindles with ER interface of CNC turning centers and swiss type automatic lathes.

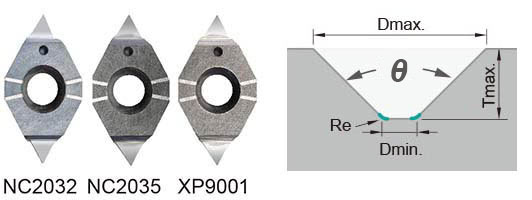

Insert 90° / 120° / 142°

• NC2032:

• NC2032: For all kinds of steel from < 40 HRC, carbon steel, alloy steel,and cast iron.

• NC2035: ALDURA coating, reduces heat and tool wear.

For steel with heat treatment up to HRC 50.

• XP9001: Mirror polished, for non-ferrous metal, aluminum, brass, copper, plastic, acrylic.