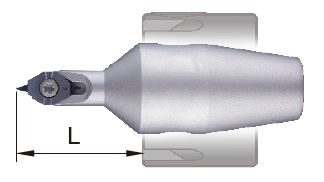

Holder

● With Balance grade: G4.0 20000 r.p.m.

● Also using for deburring tool.

Set of Ergo Nut

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

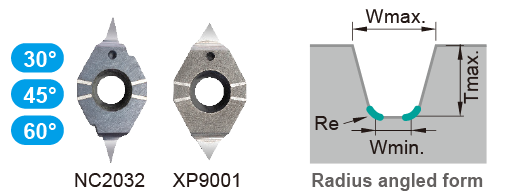

Insert - Radius angled form

- ● Fine engraving 0.2mm bottom width with narrow angle 30°, 45°, 60°.

- ● Each insert has 2 cutting edges.

- ● Also using for deburring tool.

- >> Link here for more information of deburring tool.

Insert - Radius form

- ● Fine engraving 0.2mm bottom width with narrow angle 30°, 45°, 60°.

- ● Each insert has 2 cutting edges.

- ● Also using for deburring tool.

- >> Link here for more information of deburring tool.

Holder

● With Balance grade: G4.0 20000 r.p.m.

Set of Ergo Nut

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

Insert

●

Each insert has 2 cutting edges.

Holder

● With Balance grade: G4.0 20000 r.p.m.

Set of Ergo Nut

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

Insert

● Each insert has 2 cutting edges.