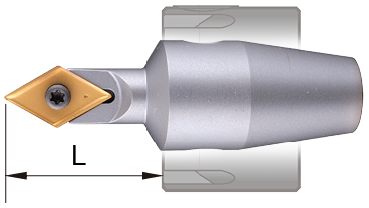

Holder

● With Balance grade: G6.3 10000 r.p.m.

Set of Ergo Nut

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

Insert

- ● NC5071: Special geometry with supporting edges, good for high speed machining.

K20F grade, for unhardened steel & cast iron.

- ● Each insert has 2 cutting edges.

Holder

● With Balance grade: G6.3 10000 r.p.m.

Set of Ergo Nut

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

Insert

Holder

● With Balance grade: G6.3 10000 r.p.m.

Set of Ergo Nut

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

Insert

- ● 90° Spotting and WSP spotting both of carbide inserts can fit on the same tool holder.

- ● Each insert has 2 cutting edges.

- >> Link here for more information of WSP Spotting insert (combined spotting and chamfering 145°+90°).

Holder

● With Balance grade: G6.3 10000 r.p.m.

Set of Ergo Nut

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

* Ergo Nut, High Strength Ergo Pin and L-Key are included.

Insert

- ● 90° Spotting, WSP spotting and corner rounding carbide inserts can fit on the same tool holder.

- ● Each insert has 2 cutting edges.

- >> WSP spotting inserts (combined spotting and chamfering 145°+90°).

- >> Corner rounding inserts (R1.0 ~ R3.0 & 1/64 ~ 1/8).