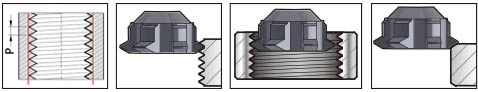

55° Parallel Pipe Thread

• NC2032:

TiAlN coating provides longer tool life.

For all kinds of steel from < HRC60, carbon steel, alloy steel and cast iron.

• XP9000:

High positive geometry and sharp edge produces excellent surface finish.

For non-ferrous material such as aluminum, brass, copper and soft material.

● See catalog for detailed specifications, please.

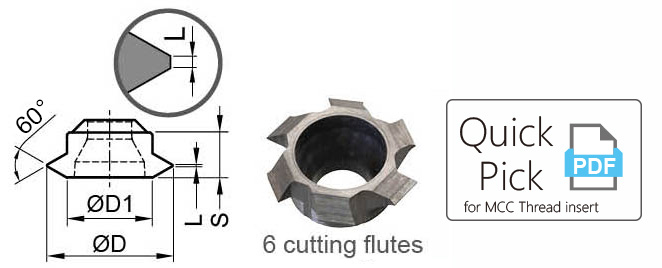

● See catalog for detailed specifications, please.60° Parallel Thread

● See catalog for detailed specifications, please.

● See catalog for detailed specifications, please.55° Tapered Pipe Thread

• NC2032:

TiAlN coating provides longer tool life.

For all kinds of steel from < HRC60, carbon steel, alloy steel and cast iron.

• XP9000:

High positive geometry and sharp edge produces excellent surface finish.

For non-ferrous material such as aluminum, brass, copper and soft material.

● See catalog for detailed specifications, please.

● See catalog for detailed specifications, please.

60° Tapered Thread

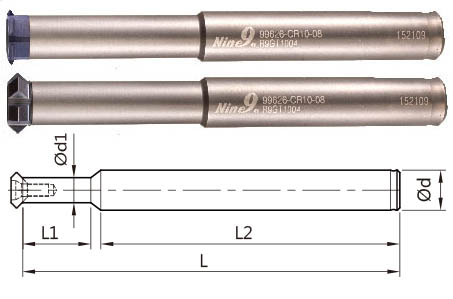

Holder

- • Various OAL holders for your choice.

- • Carbide shank holders good for fine finish.

- • Various MCC inserts can fit on the same holder.

-

-

-

-