Holder

- ● Provides high rigidity and anti-vibration.

- ● One holder supports the entire X060 series inserts.

Insert

●

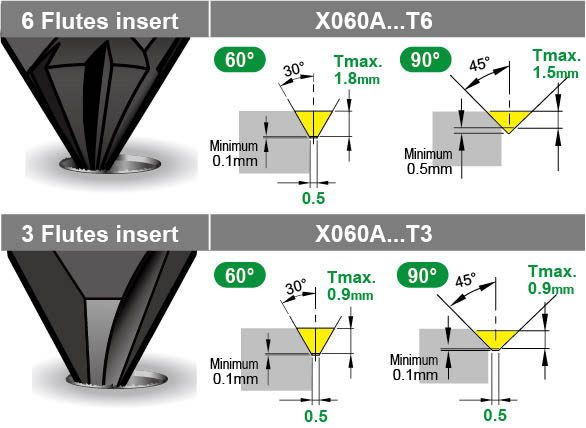

Two insert types of Nine9 NC Deburring Tool:- 3 flutes, 2 cutting-edge. Economical choice.- 6 flutes, single cutting-edge. Capable of running 6X higher feed rate● NC2032 : K20F grade. TiAlN coated carbide insert can stand very long life.

● XP9001: • For non-ferrous metal, aluminum, brass, copper, plastic and acrylic.